Qatar’s construction sector moves at a sprint: new towers, highways, rail links, stadiums, and mixed-use developments expand the skyline every year. With multiple trades working in parallel and heavy machinery in motion, the margin for error shrinks. In this environment, safety sign boards are not décor—they’re the difference between a safe task and a serious incident.

Sites often host multicultural teams speaking different first languages. Add heat, glare, dust, and night shifts, and the communication challenge intensifies. Safety signs solve a core problem: they deliver the right instruction at the right spot, in a language-agnostic, instantly recognizable format that cuts through chaos.

The Purpose of Safety Sign Boards—More Than “Signs”

Think of safety signage as a site’s nervous system. It carries signals from the HSE plan straight to the worker on the ground—clearly, consistently, and fast. When a rigger looks up at a crane exclusion sign or a welder sees a “Hot Work Permit Required” board, the policy becomes action.

From Hazard Communication to Behavioral Nudges

Great signage doesn’t merely inform; it shapes behavior. A mandatory PPE sign at a gate nudges compliance before entry. A bold warning on a scaffold triggers a quick harness check. Over time, these nudges build habits—and habits build culture.

Turning Complex Rules into Instant Actions

Policies can be long and technical. A well-designed pictogram plus a few words condenses pages of rules into a 2-second decision: stop, wear, report, or proceed.

Regulatory Alignment and Audits

Every major site is governed by a web of standards, client requirements, and HSE commitments. During inspections and audits, signage is a visible proof point that hazards are identified and controls are in place.

International Standards Referenced on Local Sites

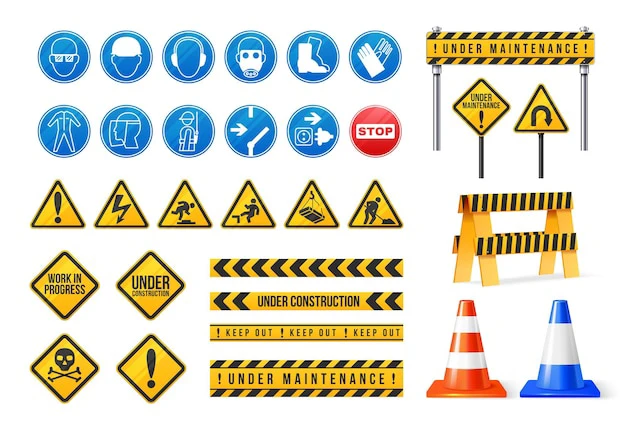

Most reputable projects align with global best practices for colors, shapes, and pictograms (for example, using red circles with slashes for prohibition, yellow triangles for warnings, blue circles for mandatory actions, and green rectangles for safe conditions). This consistency enables instant comprehension across nationalities and languages.

Color, Shape, and Pictogram Consistency

Consistency isn’t cosmetic—it’s cognitive. Workers learn to associate a shape and color with a type of risk or action. Break that pattern and you introduce hesitation, which is dangerous around moving loads or live edges.

Core Categories of Safety Signs on Qatari Sites

A robust system includes five foundational categories, each with a clear purpose:

Prohibition, Warning, Mandatory, Safe-Condition, and Fire Safety

- Prohibition: “No Entry,” “No Smoking,” “No Mobile Phones.”

- Warning: “Deep Excavation,” “Live Cables,” “Forklift Operating.”

- Mandatory: “Wear Helmet,” “Eye Protection Required,” “Use Hearing Protection.”

- Safe-Condition: “Emergency Exit,” “First Aid,” “Assembly Point.”

- Fire Safety: “Fire Extinguisher,” “Fire Hose Reel,” “Do Not Obstruct.”

Temporary Works: Excavations, Lifting, and Confined Spaces

Temporary zones—like trenches, lifting areas, or confined spaces—need mobile, weather-resistant signs. Frames and bases should withstand wind and be visible at night, with reflective or illuminated options where practical.

Bilingual Design that Works—Arabic & English

In Qatar, bilingual signage isn’t a nice-to-have—it’s essential. But slapping two texts on a board isn’t effective design.

Typography, Legibility, and Script Harmony

Arabic and English differ in script direction, stroke rhythm, and word length. Good signs balance both languages so neither looks squeezed or secondary. Pictograms should lead; short, high-contrast text supports.

Line-Length, Spacing, and Readability at a Glance

Use crisp sans-serif Latin fonts and clear Arabic typefaces that stay readable at distance. Keep line lengths short, avoid all-caps paragraphs, and leave enough white space so eyes don’t hunt for the message.

Human-Factors Placement: Where and How to Mount

A perfect sign in the wrong spot is a silent sign.

Heights, Sightlines, and Movement Paths

Install at eye level where decisions happen: before access points, at approach routes, near switches/valves, and along pedestrian walkways. Angle signs to meet the viewer—especially at corners, hoardings, and site gates.

Glare, Dust, Illumination, and Night Visibility

Qatar’s sunlight can wash out cheap inks. Choose anti-glare finishes, high contrast palettes, and reflective or lit signs for night shifts. Dust settles on everything—smooth, easy-to-clean surfaces keep messages sharp.

Materials That Survive Qatar’s Climate

Signs must endure heat, UV, humidity, and occasional sandstorms.

UV-Stable Inks, Marine-Grade Metals, and Impact-Resistant Plastics

Premium aluminum composites, coated steels, or rigid plastics (like polycarbonate or high-grade PVC) resist warping and cracking. UV-stable inks and laminates prevent fading, while stainless fixings prevent rust streaks.

Reflective Grades, Photoluminescent Coatings, and Anti-Fade Films

Reflective films (engineer or high-intensity grades) boost visibility on roads and open yards. Photoluminescent layers add fail-safe visibility during power loss. Anti-fade films extend life, saving replacement costs.

Digital and Smart Safety Signage

Construction changes daily; your signage can, too.

LED Message Boards, Sensors, and Remote Updates

Portable LED boards broadcast live alerts—heat stress warnings, wind thresholds for lifting, dust alerts, or traffic reroutes. Sensor inputs can trigger automatic messages (e.g., “High Wind—Suspend Crane Operations”).

Integrating with HSE Dashboards and Permit-to-Work

When digital signs sync with your HSE software, they can display active permits, live exclusion zones, or muster status. That tight loop between data and display shortens reaction time.

Embedding Signs into HSE Culture

Signs work best when they’re part of the training ecosystem.

Induction, Toolbox Talks, and Micro-Learning

Introduce the site’s signage system on day one. Use toolbox talks to highlight “Sign of the Week”—why it matters and what to do when you see it.

QR-Linked SOPs and Multilingual Audio Prompts

Add discreet QR codes that open short SOPs, video clips, or voice notes in multiple languages. A welder can scan and hear a 30-second reminder on hot-work protocol, right where the work happens.

Risk Scenarios—and the Signs that Prevent Incidents

Match high-risk tasks with targeted signage.

Scaffolding, Working at Height, and Crane Operations

- Scaffolding: “Do Not Alter,” “Scaffold Tag—Green/Yellow/Red,” “Toe Boards Required.”

- Working at Height: “Use Fall Arrest,” “Lifeline Connection Point,” “No Access—Unprotected Edge.”

- Crane Operations: “Slinging Area—Authorized Personnel Only,” “Boom Swing Radius,” “Lift Plan in Force.”

Hot Work, Energy Isolation, and Excavation Support

- Hot Work: “Permit Required,” “Fire Watch On Duty,” “Keep Clear—Sparks.”

- LOTO/Isolation: “Isolate Here,” “Do Not Operate—Tagged Out,” “Stored Energy Hazard.”

- Excavations: “Shoring Required,” “Access Ladder Every 7.5 m,” “No Vehicles—Weak Edge.”

Measuring Impact: From Audits to Incident Rates

What gets measured gets managed.

Leading vs. Lagging Indicators for Signage Effectiveness

- Leading: signage inspection pass rate, PPE compliance at gates, sign visibility checks, QR scan counts.

- Lagging: incident frequency, severity levels, and near-miss patterns in zones with improved signage.

Near-Miss Trends, Compliance Scores, and Response Time

Correlate near-miss drops with new sign placements. Track corrective action times after “Sign Not Visible” findings. Celebrate crews with 100% PPE compliance at signed checkpoints.

Procurement Checklist for Safety Sign Boards

A structured approach avoids rework and waste.

Material Specs, Proofs, and Mounting Hardware

- Substrate type and thickness (e.g., 3–4 mm aluminum composite)

- Ink system, laminate/film type, and UV rating

- Reflectivity class (if used) and photoluminescence rating

- Edge finishing, corner radius, and anti-glare coating

- Mounting kit: posts, brackets, anchors, anti-theft fixings

- Bilingual layout proof with pictograms and size annotations

Warranties, SLAs, and Replacement Lead Times

Define the performance period (fade resistance, adhesion), response windows for damaged signs, and stockholding of critical items (fire, first aid, muster, exits).

Maintenance: Keep Signs Performing Like Day One

A sign’s job isn’t finished at installation.

Cleaning Cycles, Inspections, and Damage Control

Schedule washdowns to remove dust films. Include signage on inspection routes. Replace cracked or vandalized boards immediately—nothing normalizes complacency like a broken safety sign.

Seasonal Checks for Heat and Sand Exposure

Before peak summer, audit for fading and adhesive creep. After high-wind events, re-check perimeter and temporary signs for stability and visibility.

Sustainability and Cost of Ownership

Better for the planet, better for the budget.

Recyclable Substrates, Low-VOC Inks, and Efficient Logistics

Choose recyclable metals and plastics where possible. Low-VOC inks improve indoor production air quality. Bundling deliveries reduces transport emissions and handling.

Reducing Reprints through Durable Design

Heavier-duty substrates and UV laminates may cost more upfront but halve replacements—shrinking costs and downtime across the project lifecycle.

Common Pitfalls—and How to Avoid Them

Avoid these silent failures:

Overcrowded Copy, Poor Contrast, and Tiny Icons

Shorten text, prioritize pictograms, and increase contrast. If a sign needs a paragraph to explain itself, it’s not a sign—it’s a memo.

Non-Standard Colors and Inconsistent Pictograms

Stick to a single standard set of icons and a consistent color system project-wide. Mismatched visuals confuse crews and slow reactions.

Implementation Roadmap for Contractors and Developers

Treat signage like any critical work package.

Survey, Plan, Produce, Install, Train, Review

- Survey: map hazards, routes, and decision points.

- Plan: create a sign schedule with sizes, materials, and mounting.

- Produce: approve bilingual proofs and samples.

- Install: follow HSE method statements; verify heights and angles.

- Train: induction/toolbox talks; share a short signage guide.

- Review: audit monthly; close snags fast; iterate with data.

Continual Improvement & Change Control

When works shift, signage should, too. Use a change log so removed or outdated boards don’t linger and dilute clarity.

Conclusion

Safety sign boards are the on-site voice of your HSE plan. In Qatar’s fast-moving, multilingual, climate-challenged construction environment, they convert policies into predictable behaviors—right at the point of risk. The best systems combine standard pictograms, bilingual clarity, durable materials, thoughtful placement, and digital agility. When paired with training, audits, and maintenance, signage reduces near-misses, strengthens compliance, and helps every worker go home safe. That’s not expense—it’s essential infrastructure for high-performing, reputable projects.

Gulfplant Qatar designs and manufactures bilingual, high-durability safety sign boards tailored to Qatar’s construction conditions—from UV, glare, and dust to night-shift visibility.

As a trusted safety sign board company in Qatar, Gulfplant Qatar delivers fast, compliant solutions with clear proofs, robust materials, and dependable after-sales support.

FAQs

1) How do I know which sign type to use at a specific location?

Start with the hazard and the action required. If you need to stop a behavior, use a prohibition sign. If a specific action (like PPE) is required, use a mandatory sign. For hazard alerts, use warning signs; for exits/first aid, use safe-condition; and for fire equipment and instructions, use fire safety signs.

2) What’s the ideal size for outdoor safety signs on large sites?

Size depends on viewing distance and speed of movement. As a rule of thumb, increase character height and symbol size with distance, and consider reflective films where vehicles move quickly or works extend into low-light hours.

3) How often should safety signs be inspected?

Include signs in weekly HSE walks and conduct monthly formal inspections. Increase frequency during peak dust/wind seasons and after site reconfigurations, crane erections, or major scaffold changes.

4) Do digital signs replace static boards?

They complement, not replace. Static boards cover permanent rules and fixed hazards. Digital signs handle dynamic risks—wind alerts, heat stress warnings, or changing traffic flows—and can be updated instantly.

5) What’s the quickest win for improving signage impact on my site?

Audit for visibility and relevance. Remove outdated boards, clean dusty faces, standardize pictograms, and relocate critical signs to decision points. Small tweaks often produce immediate compliance gains.